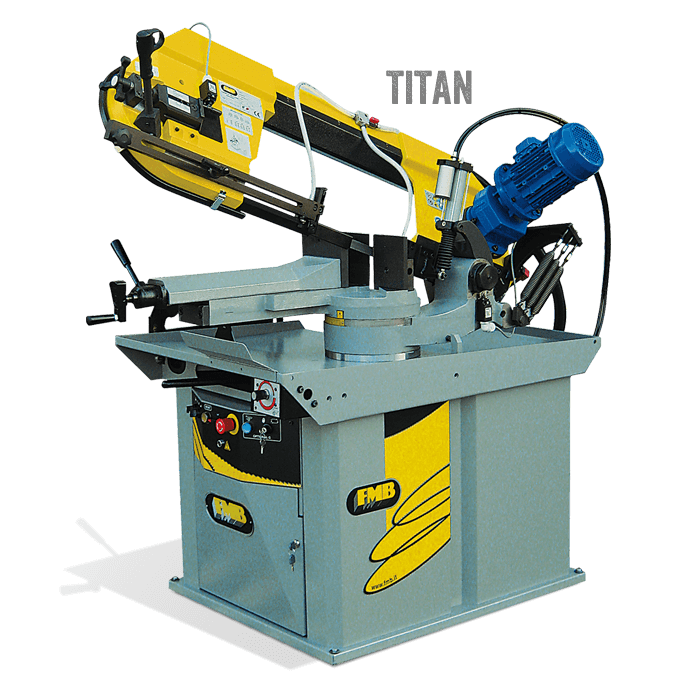

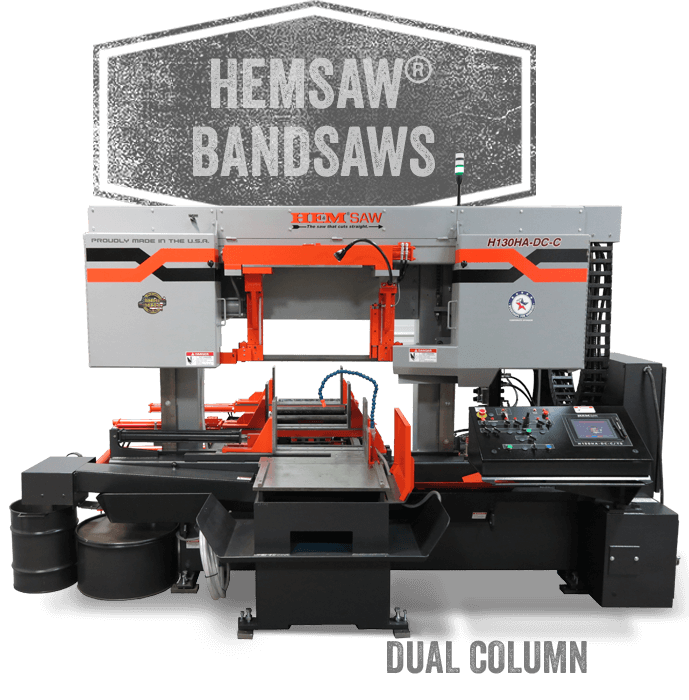

Band Saw Cutting Machine

Saws

The machine is equipped with a miter gage for cross cutting and a straight cut fence. An appropriate dust port allows for you to connect to your shopvac hose in order to clean the surface from dust generated by the machine.

The band saw can cut as precisely as a scroll saw, but it can also handle more difficult cutting tasks. Band saws are also capable of handling harder materials.